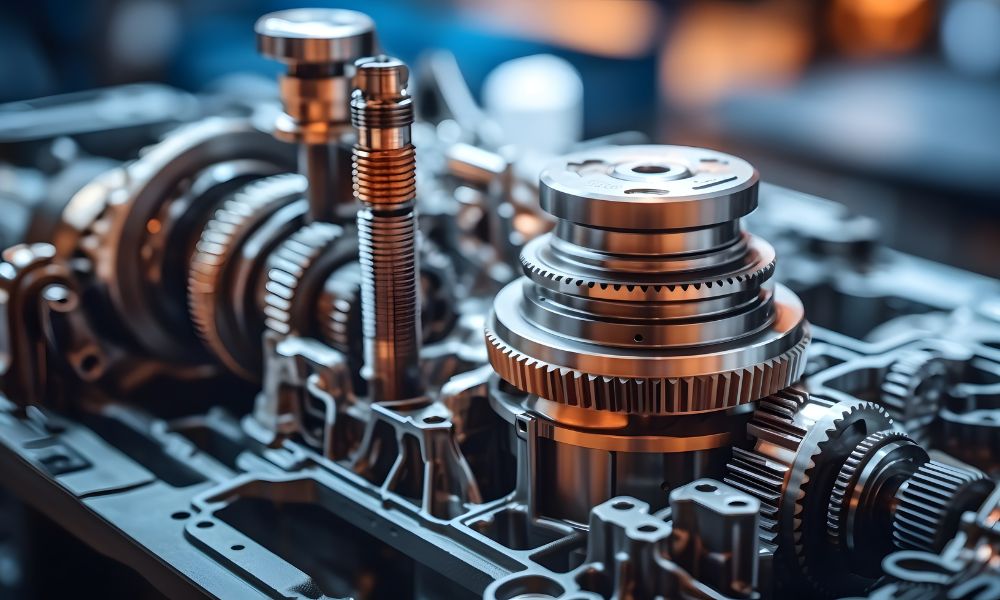

The torque converter in commercial vehicles plays a crucial role in enhancing the overall performance of the vehicle as well as the efficiency of the transmission system. This component enables smooth acceleration and deceleration by serving as a fluid connection between the engine and transmission. The system facilitates the transmission of energy to the wheels through the conversion of motor power into hydraulic pressure. Over time, torque converters may experience deterioration due to the significant demands imposed on commercial vehicles, encompassing a range of applications from passenger services to freight transportation. Consequently, it is essential to conduct regular maintenance to ensure that vehicles perform optimally over an extended duration.

Comparing and Rebuilding: A Wise Financial Decision

Fleet managers often encounter the critical decision of whether to rebuild or completely replace a torque converter when signs of failure become apparent. While replacing a torque converter may appear to be a straightforward solution, opting for a rebuild can result in significant cost savings. The process of rebuilding typically involves disassembling the existing torque converter, meticulously examining its components, and addressing any wear or damage that may be present. Organizations have the potential to significantly reduce expenses related to parts and labor, as numerous components are amenable to refurbishment. The potential savings can greatly influence a business environment characterized by tight margins, thereby enhancing overall financial performance. Opting for the Auto Repair in Sumner, WA based service is essential here.

Advantages of Sustainability and Environmental Practices

Rebuilding presents a dual advantage, being both a financially prudent decision and a more sustainable option for the environment. The reconstruction of components aligns with the principles of environmental stewardship, a recognition that is increasingly embraced within the automotive sector. Opting for rebuilding rather than replacement can assist organizations in minimizing the waste associated with the production of new components. Furthermore, it diminishes the requirement for energy and raw materials necessary for the production of new torque converters. Rebuilding contributes to the reduction of carbon footprints, a significant consideration for numerous enterprises striving to enhance their sustainability initiatives.

Enhancing the Dependability and Efficiency of Vehicles

Rebuilt torque converters often perform comparably to new units, and in some cases, even surpass them, especially when enhancements or contemporary technologies are integrated into the rebuilding process. Professionals can incorporate contemporary enhancements that boost efficiency, such as advanced hydraulic dynamics or high-performance materials capable of withstanding elevated stress levels, during the rebuilding process. Enhanced vehicle performance and reliability can be achieved, which is essential for enterprises that depend on timely deliveries and uninterrupted operations. The correlation between extended vehicle lifespans and diminished operating costs is significantly linked to enhanced performance.

In conclusion

Commercial vehicle fleets who want to enhance efficiency and lifespan should rebuild torque converters. The decision is supported by cost savings, sustainability advantages, and enhancements in performance. The restoration of torque converters alleviates financial burdens while contributing positively to environmental sustainability.