Key Takeaways:

- Turbo diesel engines use compressed air to increase efficiency and power.

- Turbocharging increases air density, allowing more fuel to be burned and resulting in higher power output.

- Turbochargers reduce pumping losses and help achieve better fuel economy.

- Turbo diesel engines offer superior torque, fuel efficiency, and durability.

- Tuning turbo diesel engines involves adjusting fuel injection, turbocharger boost pressure, and air intake/exhaust systems.

- Upgrading turbochargers can improve performance and fuel economy.

- Turbo diesel engines are used in sports cars, pickup trucks, and commercial vehicles.

- Proper maintenance and care are crucial for maximizing the lifespan of turbo diesel engines.

- Regularly changing oil, inspecting filters, and following manufacturer’s recommendations are essential maintenance tips.

- Choosing the right engine oil and following best practices for turbocharger care can extend their lifespan.

1. How do Turbo Diesel Engines Work?

A turbo diesel engine is a type of internal combustion engine that uses compressed air to increase the overall efficiency of the combustion process. By utilizing a turbocharger, these engines can produce more power and achieve better fuel economy than their naturally aspirated counterparts.

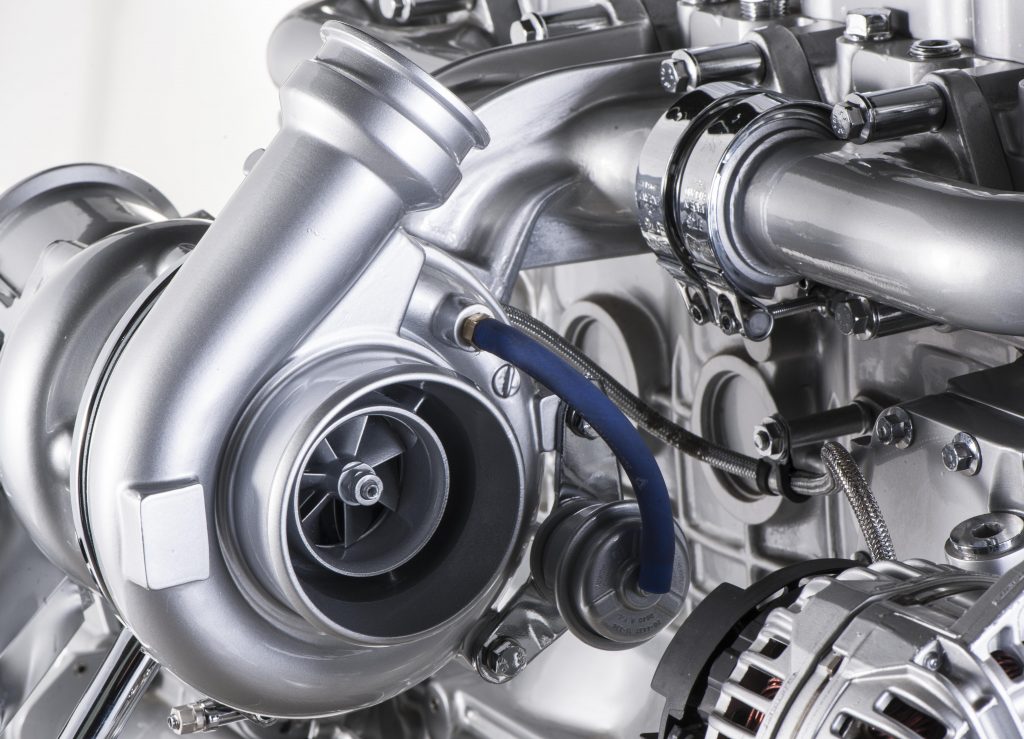

1.1 The Basics of Turbocharging

Turbocharging is a technology that has revolutionized the automotive industry. It involves using a turbine-driven supercharger, or turbocharger, to force compressed air into the combustion chamber of the engine. This results in an increased air density, allowing more fuel to be injected, and ultimately producing more power.

The turbocharger consists of two main components: the turbine and the compressor. The turbine is driven by the engine’s exhaust gases, while the compressor is responsible for compressing the intake air. The compressed air is then directed into the combustion chamber, where it mixes with fuel and ignites, creating the power necessary to propel the vehicle.

1.2 Understanding the Diesel Engine Combustion Process

Before delving into how turbochargers enhance the performance of diesel engines, it is crucial to understand the basic combustion process of these engines. Unlike gasoline engines, diesel engines rely on the principle of compression ignition to ignite the air-fuel mixture.

In a diesel engine, air is drawn into the combustion chamber during the intake stroke, and it is compressed to a high pressure ratio during the compression stroke. This compressed air reaches a temperature high enough to ignite the fuel when it is injected into the combustion chamber. The result is a more efficient and controlled combustion process.

1.3 The Role of Turbochargers in Enhancing Power and Efficiency

Turbochargers play a vital role in improving the power and efficiency of diesel engines. By increasing the amount of air delivered to the combustion chamber, turbochargers allow more fuel to be burned, resulting in higher power output.

Furthermore, turbochargers improve the overall efficiency of the engine by reducing pumping losses. Pumping losses occur when the engine needs to use energy to draw air into the cylinders. With a turbocharger, the compressed air is forced into the combustion chamber, reducing the workload on the engine and improving efficiency.

Additionally, turbochargers help diesel engines achieve better fuel economy. By maximizing the amount of air available for combustion, they allow engines to operate at lower RPMs while producing the same power output. This ensures that the engine operates in a more efficient range, resulting in reduced fuel consumption.

2. Unleashing the Potential of Turbo Diesel Engines

Turbo diesel engines offer numerous advantages over conventional engines, making them a popular choice for those seeking power and efficiency. These advantages, combined with the ability to tune the engine and the performance enhancements offered by turbochargers, make them a formidable force in the automotive industry.

2.1 Advantages of Turbo Diesel Engines over Conventional Engines

One of the primary advantages of turbo diesel engines is their superior torque output. Diesel engines inherently produce more torque than gasoline engines, and when combined with the increased air density provided by turbocharging, the torque output is further enhanced. This makes turbo diesel engines ideal for applications that require heavy towing or hauling.

Additionally, turbo diesel engines offer better fuel efficiency compared to conventional engines. The increased air density and improved combustion process result in a more complete burn of fuel, minimizing wasted energy. This efficiency, combined with advancements in fuel injection technology, allows turbo diesel engines to achieve impressive fuel economy figures.

Another advantage of turbo diesel engines is their longevity and durability. The robust design of diesel engines, coupled with their lower operating temperatures compared to gasoline engines, allows them to endure high loads and extended periods of operation. This makes turbo diesel engines a popular choice for commercial applications.

2.2 The Science behind Turbo Diesel Engine Tuning

Tuning a turbo diesel engine involves optimizing its performance by adjusting various parameters to achieve the desired power output and efficiency. The tuning process typically involves modifying the engine’s fuel injection system, adjusting the turbocharger boost pressure, and optimizing the air intake and exhaust systems.

By fine-tuning the fuel injection system, the timing and quantity of fuel injected into the combustion chamber can be optimized. This ensures efficient combustion and maximizes power output. Similarly, adjusting the turbocharger’s boost pressure allows for fine-tuning the engine’s performance characteristics, balancing power and responsiveness.

The air intake and exhaust systems also play a crucial role in turbo diesel engine tuning. Upgrading these systems, such as installing a larger intercooler or a higher-flow intake manifold, allows for increased airflow and better cooling, resulting in improved performance.

2.3 Turbochargers: Boosting Performance and Fuel Economy

Turbochargers are integral to unleashing the full potential of turbo diesel engines. Upgrading or replacing the turbocharger can significantly impact performance and fuel economy.

One option is to install a larger turbocharger, which can provide higher boost levels and improved airflow. This results in increased power output and better throttle response. Additionally, larger turbochargers often have better efficiency, reducing the overall workload on the engine and improving fuel economy.

Another option is twin turbocharging, which involves using two smaller turbochargers instead of one large unit. This setup provides better low-end torque and faster spooling, resulting in improved acceleration and responsiveness.

3. Turbo Diesel Engines in Action: Real-Life Performance Examples

Turbo diesel engines have found their way into various applications, showcasing their versatility, power, and efficiency. From sports cars to pickup trucks and commercial vehicles, turbo diesel engines continue to make their mark in the automotive industry.

3.1 Turbo Diesel Engines in Sports Cars: A Winning Combination

Sports cars are often associated with high-performance gasoline engines. However, with advancements in turbocharging technology, turbo diesel engines have made their way into the sports car segment.

One notable example is the Audi R8 V12 TDI. This diesel-powered supercar combines the elegance and performance of the R8 with the efficiency and torque characteristic of turbo diesel engines. With its twin-turbocharged V12 diesel engine, the R8 V12 TDI offers exhilarating acceleration while maintaining impressive fuel economy.

3.2 Turbo Diesel Pickup Trucks: Powering the Toughest Jobs

Pickup trucks are often used for demanding tasks, such as towing heavy loads and navigating challenging terrains. Turbo diesel engines have become the engine of choice for many pickup truck owners due to their exceptional towing capacity and torque output.

For example, the Ford F-150 Power Stroke Diesel combines the power and durability of a turbo diesel engine with the versatility of a pickup truck. With its turbocharged V6 diesel engine, the F-150 Power Stroke Diesel delivers impressive towing capabilities while providing better fuel economy than its gasoline counterparts.

3.3 The Rise of Turbo Diesel Engines in Commercial Applications

Commercial vehicles, such as buses and delivery trucks, rely on efficient and reliable engines to operate smoothly. Turbo diesel engines have gained popularity in these applications due to their fuel efficiency and durability.

One notable example is the Mercedes-Benz Sprinter, a versatile and spacious cargo van that has become a staple for many businesses. With its turbocharged diesel engine, the Sprinter offers excellent fuel economy, low-end torque for hauling heavy payloads, and the longevity required for extensive commercial use.

4. Maximizing the Durability and Longevity of Turbo Diesel Engines

To ensure turbo diesel engines perform optimally over their lifespan, proper maintenance and care are essential. By following recommended guidelines and using quality products, owners can maximize the durability, longevity, and reliability of their turbo diesel engines.

4.1 Maintenance Tips for Turbo Diesel Engines

Regular maintenance is crucial for the longevity of a turbo diesel engine. Some maintenance tips include:

- Regularly changing the engine oil and oil filter to prevent contaminants from damaging the turbocharger.

- Inspecting and cleaning the air filter to maintain proper airflow and prevent dust and debris from entering the engine.

- Monitoring coolant levels and ensuring the cooling system is functioning correctly to prevent overheating.

- Regularly checking and replacing fuel filters to prevent fuel contamination and maintain optimal fuel flow.

- Following the manufacturer’s recommended maintenance schedule for replacement of belts, hoses, and other wear items.

4.2 Factors to Consider When Choosing Turbo Diesel Engine Oil

Choosing the right engine oil is crucial for turbo diesel engines, as they operate under high temperatures and pressures. Factors to consider when selecting engine oil include:

- Viscosity: Opt for an oil with the correct viscosity range recommended by the manufacturer to ensure adequate lubrication and protection.

- Additives: Look for oil with additives designed to protect against wear, deposit buildup, and thermal breakdown.

- Synthetic vs. Conventional: Synthetic oils offer better performance, especially in extreme temperatures, and provide superior protection against engine wear.

- Oil Change Intervals: Follow the manufacturer’s recommended oil change intervals to ensure optimal engine performance and longevity.

4.3 Extending the Lifespan of Turbochargers: Best Practices

To extend the lifespan of turbochargers, it is essential to follow best practices:

- Allow the engine to idle for a few minutes before shutting it down to allow the turbocharger to cool down gradually.

- Avoid sudden acceleration or excessive throttle input after a cold start, as this can put excessive stress on the turbocharger.

- Use high-quality fuel to prevent fuel contamination, which can lead to injector clogging and subsequent turbocharger damage.

- Regularly inspect and clean the turbocharger intake and exhaust systems to ensure proper airflow and prevent the build-up of carbon deposits.

By following these maintenance practices and taking proper care of the turbo diesel engine and its components, owners can ensure optimal performance, longevity, and reliability.